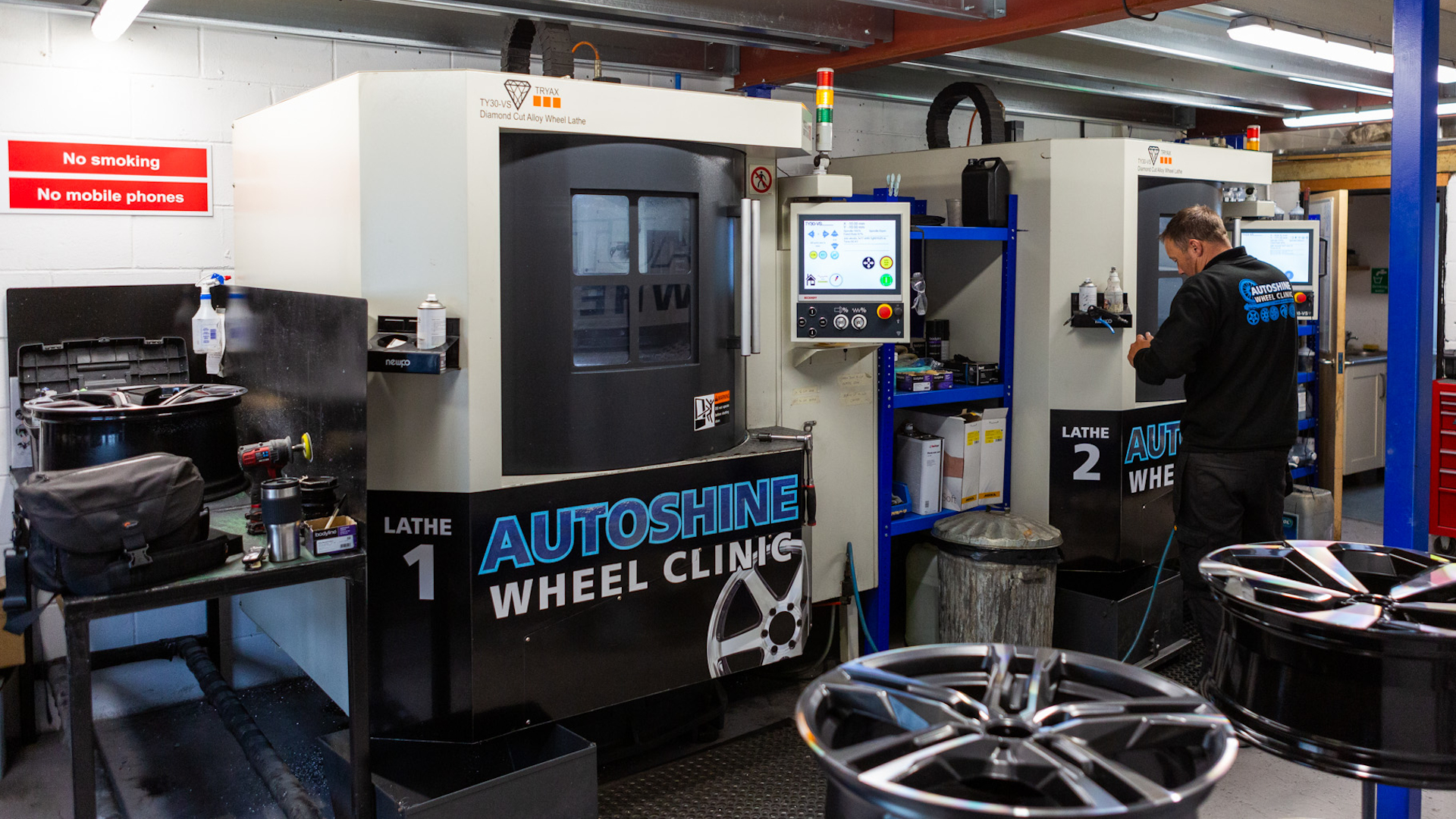

We are Cornwall's experts in diamond cutting alloy wheels. We have three alloy wheel specific lathes. These have software and programmes specifically for the correct processes needed to diamond cut alloy wheels. This ensures we remove the absolute minimum of surface material to achieve the best finish. We can adjust profiling and plots ‘on the fly’ as well as plotting each individual wheel in a few minutes to ensure we treat each wheel as an individual. Many of our competitors rely on cheap copy lathes to cut wheels, these remove far too much material and treat wheels generically. This means that should more damage be sustained in the future, recutting may not be possible.

The process of diamond cutting takes place after the primer and colour coat has been applied. We remove the wheels from the conveyor line and allow them to fully cure before mounting them into a lathe. A profile of the wheel is taken with a digital probe. This takes measurements every 0.5 of a millimetre along the face of the wheel to ensure accuracy when cutting. After plotting, we use the tooling tip to remove damage and restore the super shiny diamond cut finish. Once we are happy that the wheel has been cut to the desired standard, we carefully check over the wheel before cleaning it and adding it back onto the paint line. Once the wheel has passed through the oven, it has a corrosion barrier coat added. This additional step forms a barrier to water penetration should a stone chip the lacquer when back in use. It is an expensive process which most companies avoid due to product costs, application time and additional oven time. However, we think applying a barrier coat is a valuable step, especially considering our climate. All the above combined with our years of expertise in diamond cutting ensures we achieve the best finish possible.